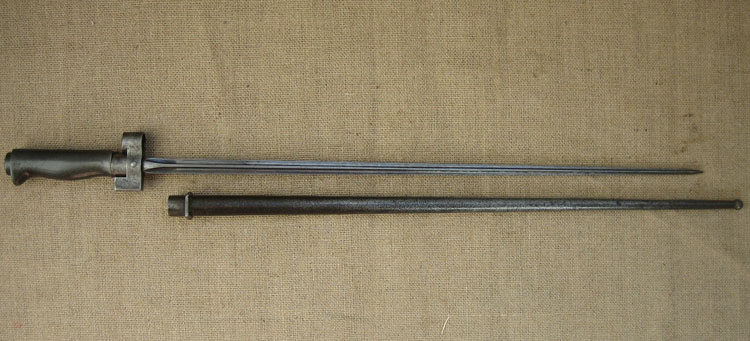

| Mle. 1886 "Lebel"

Technical data : Total length : 639 mm Was used on : Mle. 1886 "Lebel" rifle and carbine, Mle. 1892 "Berthier" rifle and carbine

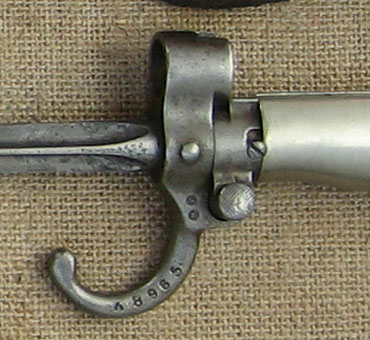

General information : The Mle. 1886 “Lebel” rifle was the first rifle using smokeless ammunition to be adopted by a major military force. The rifle itself was not of a revolutionairy design as it had a tubular magazine and a complicated charging mechanism. The advantage was purely due to the ammunition which required less cleaning resulting in a higher reliability. A fired shot would no longer produce a cloud of smoke revealing the shooter’s location.The Mle. 1886 rifle was fitted with a bayonet bearing the same name. It consisted of a cylinder in which 4 grooves were milled. This cruciform blade caused severe wounds, which healed very difficultly. With some imagination the form of those wounds looked like a rose, which led to the surname “la Rosalie”. The small non-grooved part of the blade often bears several marks referring to the proofing, the factory etc. In 1893 a first of numerous modifications was applied to the Mle. 1886 bayonet. To improve the fitting grip of the bayonet on the rifle a wider locking latch was designed. This model was called Mle. 1886-93. When the First World War broke out the French army ordered hundreds of thousands of bayonets and the national arms factories had to take measures to keep up the pace. In November 1914, when the factories realised they would not be able to produce enough bayonets within the agreed schedule, a series of propositions was made to simplify the production process. These modifications were accepted in 1915 by the French Ministry Of War and production started under the model name Mle. 1886-15. Bayonets of this pattern can be recognised by the absence of the hooked quillon and the removable handle. The aluminium-like handle of the Mle. 1886 bayonets are made of a material called Alpaca. This alloy of brass, nickel and zinc was an expensive material, especially due to the high cost of nickel. In October 1914, only 2 months after the breakout of the First World War, the production of brass handles began. In 1917 measures were taken to decrease the production costs even further by replacing the brass handles by cast iron pieces. In 1935 a final modification was made to the Mle. 1886 bayonets by cutting the blades down to about 46mm and adapting the scabbards to this new length. The new pattern would be called Mle.1886-35. Not all shorter Mle. 1886 bayonets which lost those missing centimetres only in 1935. The long, small blade of the 1886 was quite vulnerable and many of them broke during training, combat or any other occasion on which considerable pressure was applied. When that happened and replacements were not available, the blade was re-pointed and returned to the soldier. Some of these bayonets were altered into very effective trench daggers as well. A combination of all these modifications and changes of materials have created an interesting field of collecting. Alpaca handles can be found with quillon and with the quillon removed. Brass handles exist with quillon, with the quillon removed and produced without quillon. The cast iron pieces were never made with quillons. Known makers : Manufacture Impériale de Chatelleraut Images.

© www.bajonet.be |

||||||||||||||||||||||||||||||